Case study for a centralised water softening plant to meet site’s demand for continuous soft water.

Background – Managed Water Services have been assisting this food and beverage client with the servicing of the pre-treatment plant on site for over 8 years.

As the site has expanded it soon became apparent that the current capacity of the existing multiple location water softeners had been exceeded and were no longer fit for purpose. The demand for soft water was such that a centralised water softening plant was required.

Site were also keen to minimise manual handling as engineering staff were filling various brine tanks with 25Kg bags of tablet salt on a regular basis. Time was also being spent by site staff in carrying out weekly soft water and plant checks which site wanted to minimise.

Proposed solution –

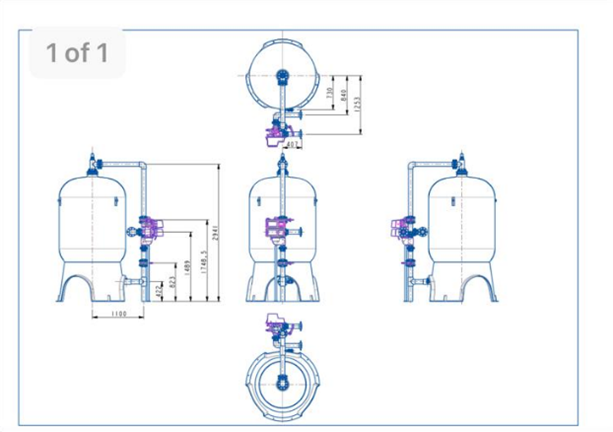

Managed Water Services designed a centralised water softener plant that could cope with site’s demand for soft water. This included an element of future proofing as production is forecast to increase significantly in the next four years.

Managed Water Services undertook a in depth survey on the site’s supply water quality and hardness along with water demand from the production. We were then able to precisely calculate the volumes of resin required to cope with the volume of water that production required.

Valve types were also taken into consideration along with the volumes of brine required.

Less manual handling –

Managed Water Services designed a salt saturator system that could take a bulk pressure delivery of salt thus eliminating the need for site engineering staff transporting 25Kg bags of tablet salt around site to various locations. The salt saturator also ensured a solution of 100% brine was always available. This will ensure that the water softeners would regenerate correctly as and when needed.

Saving money –

Centralising the softening facility was a cost effective way of ensuring the site’s demand for continuously treated water. Replacing softeners in various locations around site would not be cost effective when compared to centralisation.

Bulk delivery of salt is also extremely cost effective when compared to purchasing the same volumes in bags of tablet salt. This has drastically reduced the consumable cost going forward.

Benefits –

- Centralised water softener plant:

- Capacity to expand as they see fit the need for localised water softening plants is no longer required

- Labour saving as manual filling of numerous brine tanks now eliminated

- Reduction in capital expenditure

- Reduction in consumable costs

- Reduction in on-going service costs

- Site now have full confidence in their water supply

- Site have saved time in carrying out unplanned de-scaling where old softening plant had failed

- There is a marked improvement in heat transfer where scale is no longer present

- The requirement to have pallets of salt delivered and transferred around site with manual handling issues has been eliminated

- Less ppms for site engineers as the new plant is centralised in one location.

- Fully automatic system with capacity regeneration programme

- Fully commissioned by MWS upon completion

Conclusion – Managed Water Services will continue to support this site with their ever growing expansion and ensuring that soft water is available as required to suit their needs.