The four key rules to running a hot and cold water system safely are: Keep hot water hot, Keep cold water cold, Keep the system clean, Keep the system moving.

We focused our last update on the importance of keeping water moving and avoiding stagnant conditions. In this article we are going to focus on the importance of keeping hot water stored at the target temperature. The information below applies to any hot water storage facility with a volume in excess of 15 litres.

Why we need to keep hot water hot

Calorifiers and hot water cylinders utilise primary heating circuits (from a boiler), electric immersion heaters, a gas flame or an external heat exchanger to heat up the water stored within.

Technical Guidance from the Health & Safety Executive – HSG 274 Pt2 – states that the general principles of design should avoid the temperatures that encourage the growth of legionella bacteria, and the following should be considered:

- Maintaining a supply temperature of at least 60°C from the heat source and / or the calorifier

- The hot water circulating loop (if present) should be designed to give a return temperature to the calorifier of at least 50°C (55°C in healthcare)

- The calorifier’s capacity and recovery rate should be selected to meet the normal daily fluctuations in hot water use without any significant drop in the target temperature

- Where more than one calorifier is used, they should be connected in parallel and deliver water temperature of at least 60°C

Sounds easy, right? But it is surprising how many calorifiers do not tick all the above boxes.

Maintaining a supply temperature of at least 60°C from the heat source and / or the calorifier

At least 60°C is generally the target temperature for storing significant amounts of hot water as there is a relatively quick (2 minutes) kill of the majority of the legionella bacteria population that may be present in the water. So, storing your hot water at this temperature is a really good control strategy for keeping the system, from a microbiological perspective, clean.

BUT! If we are storing hot water at less than 60°C then the time it takes for bacteria to be killed off increases significantly. If a calorifier is storing hot water at 50°C it will take 2 hours for a majority bacteria population kill and this is unlikely to be enough time as the water will have left the calorifier to satisfy the demands of the system.

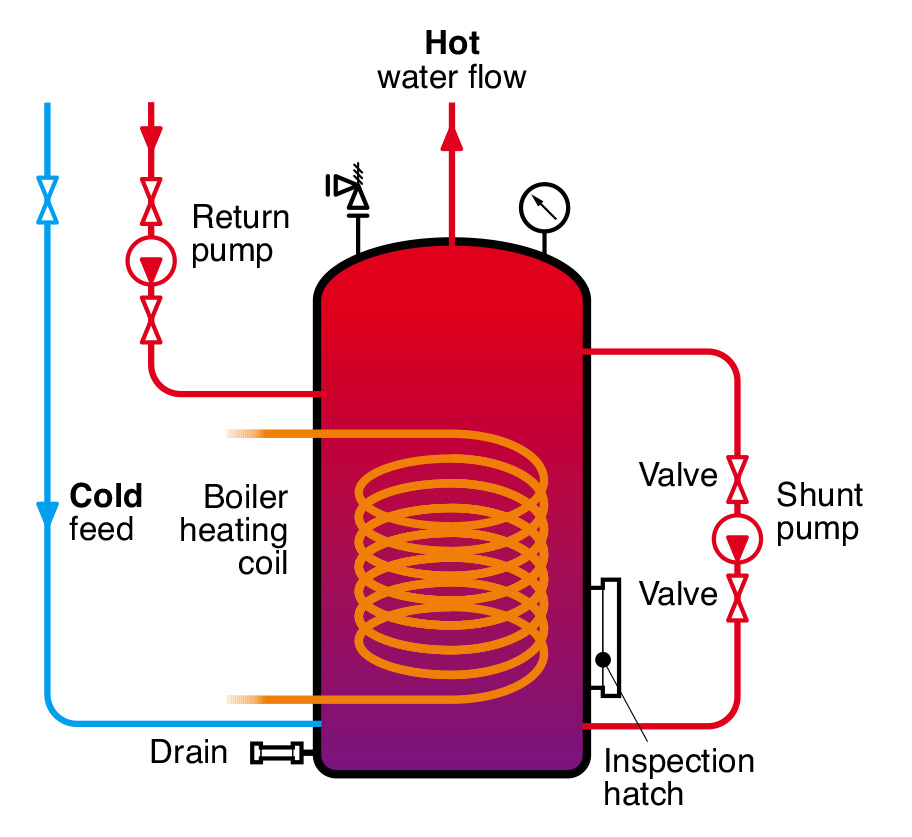

The plant should be designed to ensure that the whole body of water is heated to the target temperature (at least 60°C). This parameter can sometimes be difficult to meet however as the design of the calorifier may give rise to what is called “stratification” which is the gradual decrease in hot water temperature the lower down the vessel you test. Hot water may be at 60°C at the top, but it could be much lower at the bottom. To overcome this, it may be beneficial to fit a de-stratification or shunt pump to move water from the top of the calorifier (hottest part) to the bottom (coolest part). See Fig 1 below

The hot water circulating loop (if present) should be designed to give a return temperature to the calorifier of at least 50°C (55°C in healthcare)

Where hot water is re-circulating around the system then this should be at a minimum temperature of 50°C (55°C in healthcare). Re-circulating water at this temperature avoids conditions for bacteria populations to increase significantly and it will also mean that water is constantly being circulated back to the calorifier, where it is being heated to at least 60°C again, and achieving a quick kill.

All of the re-circulation system should be working effectively and at the above temperatures, if it isn’t then water will stagnate, and it can cause significant issues.

Fig 1 below shows the return pump which circulates water around the system and then back to the calorifier.

Fig. 1

The calorifier’s capacity and recovery rate should be selected to meet the normal daily fluctuations in hot water use without any significant drop in the target temperature

Whatever time you carry out your temperature checks on your calorifier it should be meeting the target temperature. 8am on a Monday morning? It should be at the target temperature. 2pm on a Friday afternoon? It should be at the target temperature. 5pm on a Thursday evening? It should be at the target temperature. If there is fluctuation in the temperature during the day and it cannot cope with demand, then it may need to be re-configured or even replaced.

Where more than one calorifier is used, they should be connected in parallel and deliver water temperature of at least 60°C

It is very common for 2 or sometimes even more vessels to be installed in a premises to cope with demand. Where this is required, the system should be designed so that water is drawn from all vessels equally to prevent water stagnation from occurring. If a “buffer” vessel is used to increase storage capacity then this will have the same strict guidance placed on it as a calorifier – i.e. it must store hot water (the whole body of water) at the target temperature (normally 60°C) and meet daily demand without a significant drop in temperature.

Can I turn my calorifier off overnight?

It may be that this question is asked a lot more at this time than ever before with the rising cost of energy. The answer is yes, but you must make sure, normally with the help of a timer control, that the contents of the cylinder are heated back up to the target temperature before use. For instance, if an office block wanted to turn the calorifier off overnight, then the timer could be set to switch off at 7pm after the last person leaves and come on again at 5am, so when the early worm arrives at the office at 6:30am the hot water is being stored and re-circulated at the target temperatures. Figure 2 below shows September’s temperature profile of a calorifier on one of our customer sites. The calorifier is timed to turn off overnight but comes on early enough to heat up to hit or exceed the target temperature before use and throughout the period of operation.

Fig. 2

Need some support or guidance?

If you have any concerns about the safe operation of your hot water system, then do not hesitate to contact us at Managed Water Services for support and guidance.

- Contact your MWS account manager

- See the Knowledge Library or FAQs on our website